Introduction:

Polyetheretherketone (PEEK) is a semi-crystalline polyaromatic thermoplastic polymer with many excellent properties, such as high heat resistance, high mechanical properties and chemical stability, self-extinguishing and resistant to most chemicals. Medical peek materials are corrosion-resistant to chemical reagents and solvents, resistant to radiation, and have good biocompatibility. They have been recognized by many medical device manufacturers and surgeons in the medical field and have been used in the fields of spine, trauma and joints.

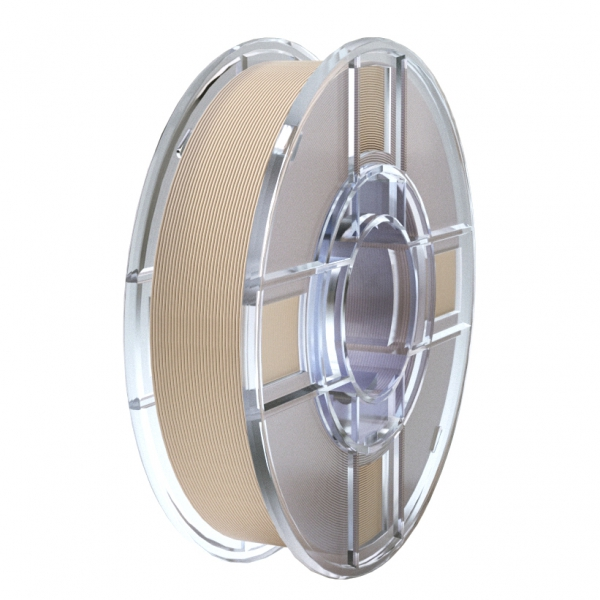

Material wire diameter: 1.75±0.03mm

Wire net weight: 0.25/0.5/1kg

3D printing peek filament is suitable for FDM process. As a representative material of special plastics, polyetheretherketone peek material has excellent mechanical properties, self-extinguishing property, heat resistance, radiation resistance, corrosion resistance of most chemical reagents and solvents, and good biocompatibility. This 3D printing peek filament combines a variety of excellent properties and can be used as a medical implant-grade peek material for precision printing of electronic parts and medical devices.

Material name: eSUN MED PEEK

Material wire diameter: 1.75±0.03mm

Wire net weight: 0.25/0.5/1kg

Printing temperature: 400℃~450℃

Platform temperature: 100℃~160℃

Box temperature: 80℃~140℃

Printing speed: 20~50mm/s

Implant-grade PEEK product applications:

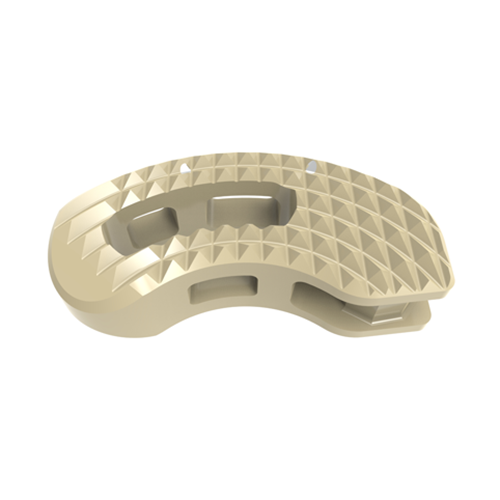

Instead of titanium alloy plates, skull repair patches are made;

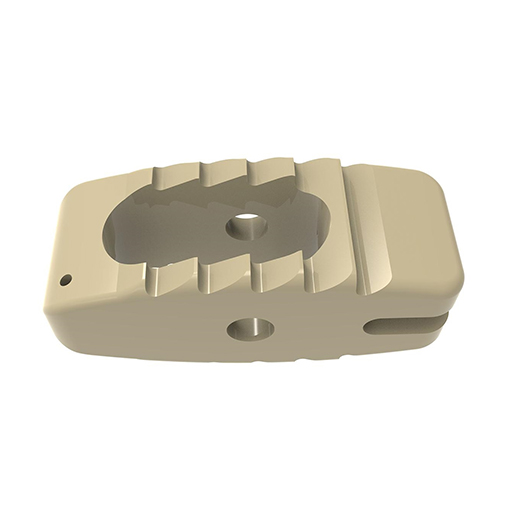

Instead of titanium alloy, intervertebral fusion cages are made to repair the spine;

Instead of titanium alloy or stainless steel, make orthopedic fixation plates;

Medical peek materials can be used in dental implant accessories, such as temporary abutments, healing caps, healing abutments, etc.

Production process: Medical FDM high-performance 3D printer